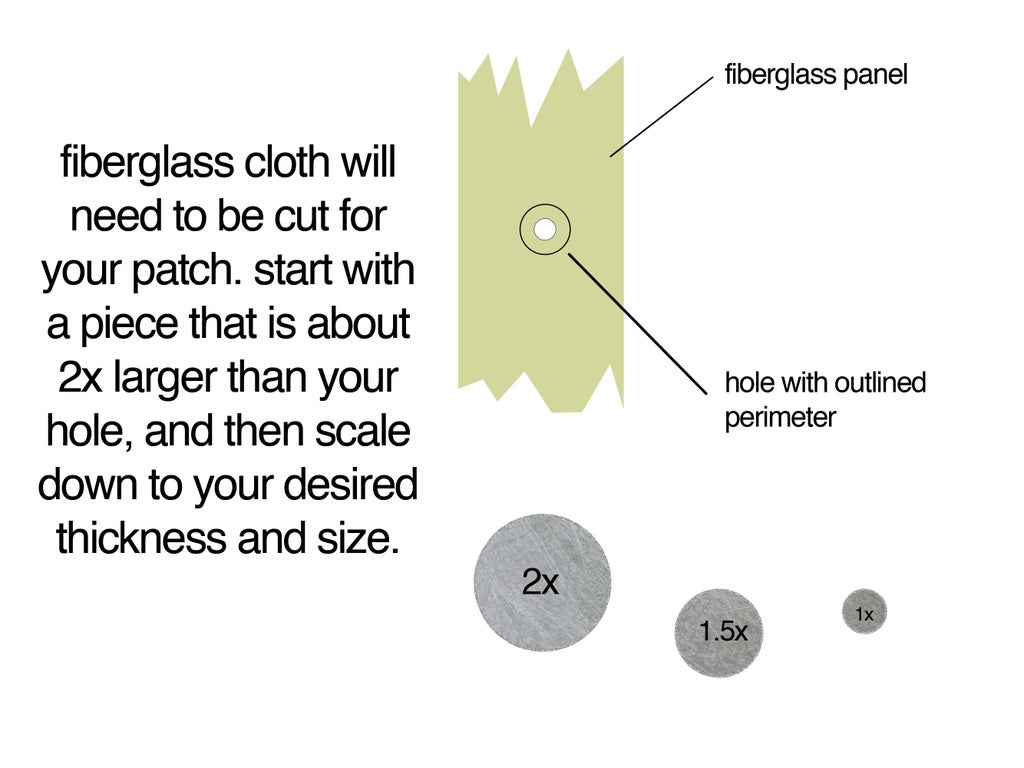

As with applying the resin make sure you completely cover all sections of the interior mold with the fiber cloth.

Direction of fiber wrap in a fiberglass sheet lay up.

Fibers can be oriented in any direction between 0 and 180 although fiber orientation beyond 90 is usually referred to as a negative angle value.

The list below contains common designations for this material.

Common lay up terms and conditions quasi isotropic isotropic means having the same properties in all directions.

Carbon fiber carbon fiber is known for being light weight strong and for having great cosmetics.

Fiberglass is the actual cloth or mat made up of glass fibers.

Lay up carbon fiber recap.

Can you double up paper back insulation to fill deeper space by using 2 by 6 board studes as framing.

We put 18 gauge steel in the metal brake and finished the bend over a table edge.

Can i put the peper face against the outside wall and the second piece put fiberglass sides together so the paper face of the inside paper is against the sheet rock.

Most carbon fiber and fiberglass tubing on the market today utilizes a combination of two or more of these orientations.

Quasi isotropic means having isotropic properties in plane.

For example in a 3k fiber fabric each bundle of fiber has 3000 filaments in it.

The fabric to resin ratio was carefully calculated to yield a maximum of 35 resin content and process demonstrate how to produce low porosity or entrapped air bubbles large voids and microscopic porosity within the laminate.

Fiberglass resin impregnating technique.

A quasi isotropic part has either randomly oriented fiber in all directions or has fibers oriented such that equal strength is developed all around the plane of the part.

However this section will cover glass fiber specifically.

Subsequent layers of cloth are placed on the first layer taking care to alternate the weave direction 45 degrees for bidirectional and 90 degrees for twill fabrics.

We mounted our metal to keep it from flexing and applied partall a parting wax.

Diamondwrap hp is engineered to provide strength that enables a pipeline to be restored to maximum allowable operating pressure maop without shutting down.

It is often used in the automobile sporting goods and aerospace industry.

For example a 135 fiber angle is equal to a 45 angle.

Quickly press sheets of carbon fiber cloth into the mold.

The following video demonstrates the basic lay up technique to fabricate a fiberglass laminate.

Description diamondwrap hp is the leading carbon fiber wrap system used to rehabilitate and restore original operational strength to dented gouged corroded and eroded pipelines.

A yard of carbon fiber cloth has millions of microscopic filaments all bundled together.

As noted above the fiber does not have to be glass.